The most common cause of manufacturing defects in furniture and cabinet plants that occur after initial drying (nearly 85%) is incorrect moisture content control, and allowing for subsequent expansion and contraction in the construction of the project.

Wood is an organic material, and like most things, will slightly expand when its moisture increases, and will shrink slightly when it dries. Imagine a sponge or a sheet of paper, how it will expand and wrinkle when it gets damp, and shrink when it dries.

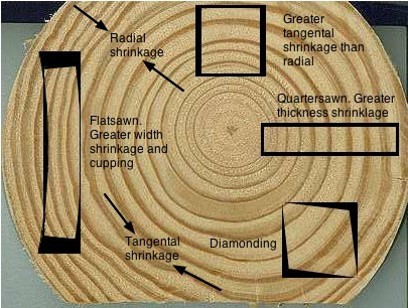

The equilibrium moisture content (EMC) is when internal moisture changes in wood are based on relative humidity and temperature and is in “equilibrium” with its environment. Even a house, with modern air conditioning and heating, is always changing its humidity level, and the wood in the house is always changing its moisture content to equalize with temperature and humidity The wood is always in a constant state of expansion and contraction. That’s why some furniture, especially drawers and door, may stick or jam at certain times of the year. As shown in the picture below, the grain geometry in a board determines how it will shrink. A good sawyer always keeps this in mind when milling logs.

A common misconception and something we hear all the time is “My Lumber Has Been Air Drying for Years, So Its Got the be “Really” Dry.” However, it doesn’t matter how long the wood has been air drying, it can not get below the Equilibrium Moisture Content (EMC ) that the conditions allow. The Average yearly EMC of air dried wood in Huntsville is 13.7%, however drying wood in a warm barn or other area where the local relative humidity is lower (temperature is higher) will allow further drying. Kiln dried lumber stored outside will regain moisture eventually back to local EMC.

The equilibrium moisture content (EMC) is when internal moisture changes in wood are based on relative humidity and temperature and is in “equilibrium” with its environment. Even a house, with modern air conditioning and heating, is always changing its humidity level, and the wood in the house is always changing its moisture content to equalize with temperature and humidity The wood is always in a constant state of expansion and contraction. That’s why some furniture, especially drawers and door, may stick or jam at certain times of the year. As shown in the picture below, the grain geometry in a board determines how it will shrink. A good sawyer always keeps this in mind when milling logs.

A common misconception and something we hear all the time is “My Lumber Has Been Air Drying for Years, So Its Got the be “Really” Dry.” However, it doesn’t matter how long the wood has been air drying, it can not get below the Equilibrium Moisture Content (EMC ) that the conditions allow. The Average yearly EMC of air dried wood in Huntsville is 13.7%, however drying wood in a warm barn or other area where the local relative humidity is lower (temperature is higher) will allow further drying. Kiln dried lumber stored outside will regain moisture eventually back to local EMC.

Lorem Ipsum is simply dummy text of the printing and typesetting industry.